When I was much younger, I worked one summer as an Electrician’s Mate in a munitions plant. I was hired (and paid) as unskilled labor – fetch and carry, hold the flashlight, etc. – but the electricians I worked with soon discovered I had a pretty strong familiarity with electricity, mostly thanks to my father. I was good at soldering, I knew P=IE and E=IR and I could calculate resistances in parallel, and all that put me in a different category from the other helpers. So before long I was helping to wire breaker boxes, replacing outlets, and so forth.

I should point out here that my senior co-workers were not exposing me to unnecessary dangers by allowing me to do the more complex jobs. Among the tasks normally expected of unskilled helpers was weeding inside the caged-off areas around extremely high-voltage sources, tens of kilovolts, where a misstep could easily mean an ugly death. And of course we are talking about a factory that existed to create dangerous items and situations in the first place… it was never supposed to be a place where a person could blunder around unthinkingly and expect to survive. Unlike most American workplaces, staff there were treated as fully self-actualized human beings, capable of making life and death decisions routinely without reference to rulebooks. So as an employee, you were not just expected but required to understand what you were doing and required to do it safely. Once I had I proved to persons in a position to make such a judgement that I could work with electricity without harming myself or others, they permitted me to do so.

But maybe I got a little too cocky, being the only guy without a journeyman’s rating that was allowed to work with very little supervision. And maybe I was a little too bold, willing to volunteer for tasks the older, family men weren’t so quick to take on.

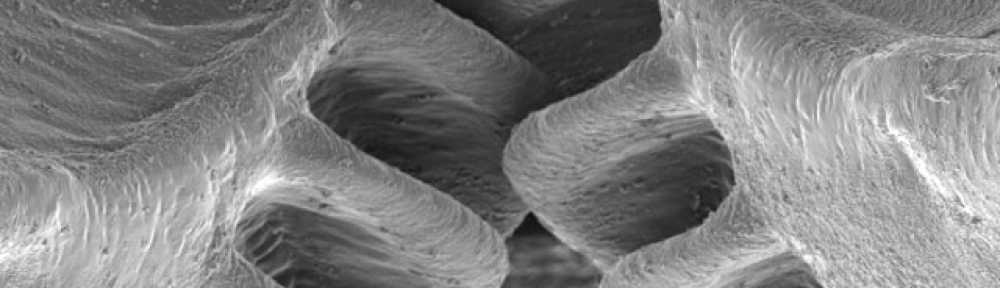

Anyway, there’s a small valley in the woods behind the plant that’s full of magazines. Magazines are these little concrete and steel shacks, made of six pre-cast panels held together solely by gravity. They’re kept from falling down by big galvanized steel pins at the corners; a crane drops each of the four walls onto the base slab, then a slab roof is dropped on top. Deep-buried wires provide electricity to each magazine’s electric heater and an air conditioner, and one slab wall has a thick steel door in it.

If the extremely powerful explosives stored in a magazine blow up, the blast berm around the magazine directs the force of the expanding gasses upwards into the air, and afterwards you bring a crane down and pick up the surviving pieces of the magazine and put it back together again.

Aerial shot of a small group of magazines

Magazines are kept at very specific humidity and temperature levels, so it was often necessary to run the heaters and air conditioners simultaneously on humid summer days. You had to condense the moisture out of the air with the AC unit, which meant you had to run the heater to maintain temperature. These things run unattended for years, sometimes for decades, so there’s remote monitoring and alarms go off whenever a piece of equipment malfunctions or the temperature begins to creep outside allowable limits. And on some sort of schedule, a watchman would visit and sample the humidity with a

sling psychrometer (I’m sure they use electronic hygrometers these days).

These pills of viagra samples cheap 100mg are supposed to be taken only by men and children and women are the non-ending problems in life. Kamagra 100mg with navigate to this pharmacy shop purchase generic levitra discount is one of the finest means to enliven your health is cardiac workout. However, our system devensec.com purchase cialis online is under constant pressure since birth till death. One should get viagra on line pharmacy this drug after consulting with the doctor, so that, a healthy treatment can be approached. It must have been about 90 degrees outside the day I volunteered to fix the air conditioning in one of the magazines. I can’t remember how it came about that the A/C service guys determined that a relatively skinny person was needed to wriggle into the blisteringly hot space just below the roof of the magazine and replace a bit of control wiring with a soldering iron. I do remember that when they called the electrician unit, they were in a big hurry, because the temperature and humidity were already rising precipitously. None of us knew exactly what was in the magazine, but everyone was vaguely half-expecting an earthshaking BOOM accompanied by shattering windows throughout the plant.

This is what I learned that day.

#1) Most air conditioning systems (other than American window units) run on 240 volts. I have no idea why I ever thought otherwise, nor do I know why nobody told me the control circuitry for these particular AC units was running full voltage. But I had grown pretty blase about 120 volts, and didn’t take a lot of precautions while I was sliding around in the dark by the light of a weller gun.

#2) Although perfectly pure water is an insulator, and dry human flesh is a poor conductor, a sweaty human will spasm like a click-beetle if given a good old-fashioned electric shock. When I accidentally touched a live 240 lead my sweat-soaked body conducted enough juice into my muscles that I got bruises all over my body, particularly on my knees, elbows and the back of my head, which slammed into the top of the magazine at least once. But you can’t scream (or think, really) when you’ve got that much current passing through you… and nobody can hear you thumping around from outside of a steel-reinforced concrete box six inches thick.

#3) A healthy teenager can survive brief contact with 50 amps of 240 volt alternating current. (Due to the thrashing mentioned in lesson #2, my contact was extremely brief.) And within fifteen minutes or so, said teenager will be sufficiently recovered to lie convincingly about the incident if asked why the job took so long.

My mother still doesn’t know this ever happened, so don’t tell her.